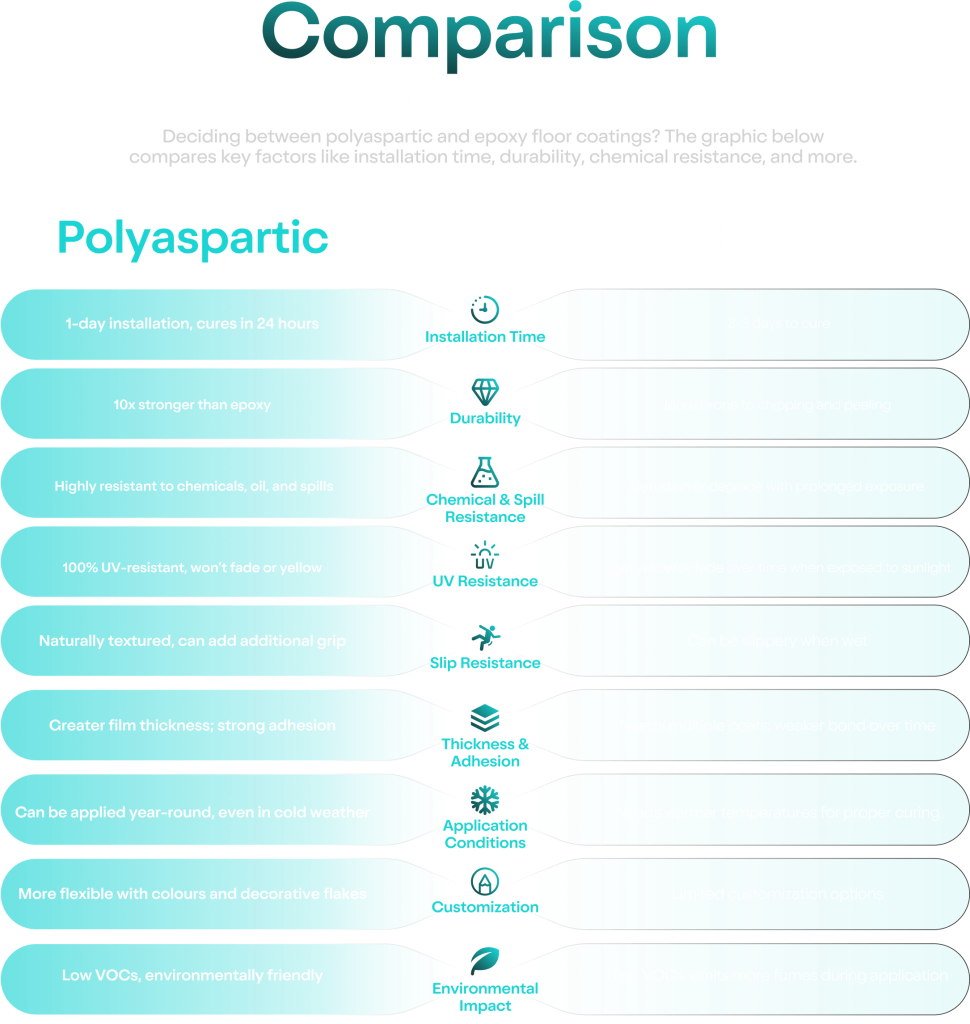

Choosing the right floor coating for your garage, commercial space, or basement can be overwhelming. Among the most popular options, polyaspartic vs epoxy is a hot topic. Both offer solid benefits, but knowing the key differences can help you make a decision that adds lasting value and performance.

In this comparison guide, we break down the major differences, pros and cons, and what you need to know before investing in a floor coating. Whether you’re a homeowner looking to elevate your garage or a business owner needing durable flooring, this guide’s got you covered.

What Are Epoxy and Polyaspartic Floor Coatings?

Before diving into the comparison, let’s define what each option is:

Polyaspartic floor coatings

Polyaspartic floor coating is a type of polyurea that cures rapidly and provides a highly durable, UV-stable surface.

Epoxy floor coatings

Made from a combination of resin and hardener. When mixed, they form a rigid plastic material that’s strong and resistant to degradation.

Both coatings are used to protect concrete floors, improve aesthetics, and provide resistance to chemicals, abrasions, and impact.

1. Installation: Speed and Convenience

If installation time matters to you, polyaspartic has the edge.

Epoxy coatings can take 2 to 3 days or more to cure, depending on environmental conditions.

Polyaspartic floor coatings can fully cure in as little as 24 hours, meaning you can walk and park on it the next day.

This fast turnaround makes polyaspartic a top choice for both residential and commercial projects where downtime is costly.

2. Durability and Longevity

When comparing polyaspartic floor coating vs epoxy, polyaspartic clearly comes out ahead in terms of performance and longevity.

Polyaspartic coatings

- UV-stable (no yellowing over time)

- More flexible, which reduces cracking

- Resistant to extreme temperatures and chemicals

Epoxy floor coatings

Prone to chipping and cracking

Not UV stable (can discolor when exposed to sunlight)

Slower to cure, which can impact overall finish quality

Did You Know?

Polyaspartic coatings are often rated to last 15–20 years, whereas traditional epoxy coatings may need replacement or recoating after 5–10 years depending on traffic and exposure.

3. Aesthetics and Customization

Both coatings offer custom options, but polyaspartic offers a more vibrant, long-lasting finish.

With polyaspartic, color flake systems are more deeply embedded, resulting in a smoother finish.

- Epoxy can be customized as well, but the finish may fade or yellow over time, especially in sunlit areas.

Whether you’re going for a sleek, modern look or something more industrial, polyaspartic is more likely to maintain its appearance.

4. Temperature Sensitivity

If you’re applying the coating in a cold garage or during seasonal transitions, this could make or break your choice.

Epoxy typically needs temperatures above 50°F to cure properly.

Polyaspartic coatings can be installed in sub-zero temperatures, making them ideal for Canadian winters.

So, if you’re asking yourself what is better than epoxy for garage floor applications during winter, polyaspartic is your answer.

5. Maintenance and Resistance

Both options are low-maintenance, but again, polyaspartic takes the lead.

Polyaspartic:

- Easier to clean

- More resistant to staining from oil, gas, salt, and other chemicals

- Does not peel or flake under pressure washing or heavy traffic

Epoxy:

Susceptible to staining if spills are not cleaned quickly

Can delaminate over time under hot tires or moisture intrusion

If you’re looking for peace of mind with minimal upkeep, polyaspartic wins this round too.

6. Cost Comparison

Let’s talk dollars and cents.

Epoxy coatings are generally less expensive upfront, which is why they’re still widely used in budget-conscious projects.

Polyaspartic coatings have a higher initial cost but offer greater longevity and fewer repairs down the line.

So, if you’re investing for the long haul, polyaspartic may offer better value.

When to Choose Epoxy Over Polyaspartic

When it comes to protecting and elevating your concrete floors, polyaspartic floor coating stands out as the smarter, longer-lasting choice. While epoxy has been around for decades, polyaspartic technology brings next-level performance that meets the demands of modern homes and businesses.

Here’s why more people are making the switch:

- Faster Cure Time: Walk on your floors in 24 hours and drive on them the next day—no long wait times like epoxy.

Superior Durability: Resistant to UV rays, chemicals, abrasions, and hot tire pickup—polyaspartic holds strong where epoxy often fails.

Cold Weather Application: Unlike epoxy, polyaspartic can be applied in cold temperatures, making it ideal for garages in Canadian climates.

Low Maintenance: Spend less time cleaning and more time enjoying a floor that resists staining, cracking, and yellowing.

Longer Lifespan: Polyaspartic coatings often last 15–20 years or more, offering long-term value with fewer touch-ups or reapplications.

Whether you’re upgrading your garage, workshop, commercial space, or operational facility, choosing polyaspartic means choosing the best.

Make the Smart Choice for Your Floor!

Your garage deserves better than cracked, stained concrete or yellowed coatings. Upgrade with a coating that performs like it should and looks even better. At QuickCoat, we specialize in premium polyaspartic floor coatings that offer unmatched durability and style.

Ready to find out what is better than epoxy for garage floor surfaces? Explore our services and get your free quote today!