When it comes to garage upgrades, flooring is one of the most overlooked yet impactful elements. Choosing between polyaspartic vs. epoxy garage floor coating is a common dilemma for homeowners looking to protect their floors while enhancing their space. In this blog, we’ll walk through how these two coatings compare across key areas, including durability, installation, maintenance, and cost. By the end, you’ll know exactly which option best suits your garage needs. Whether you’re planning a full renovation or a surface refresh, this guide will help you make a confident choice.

Durability and Performance Over Time

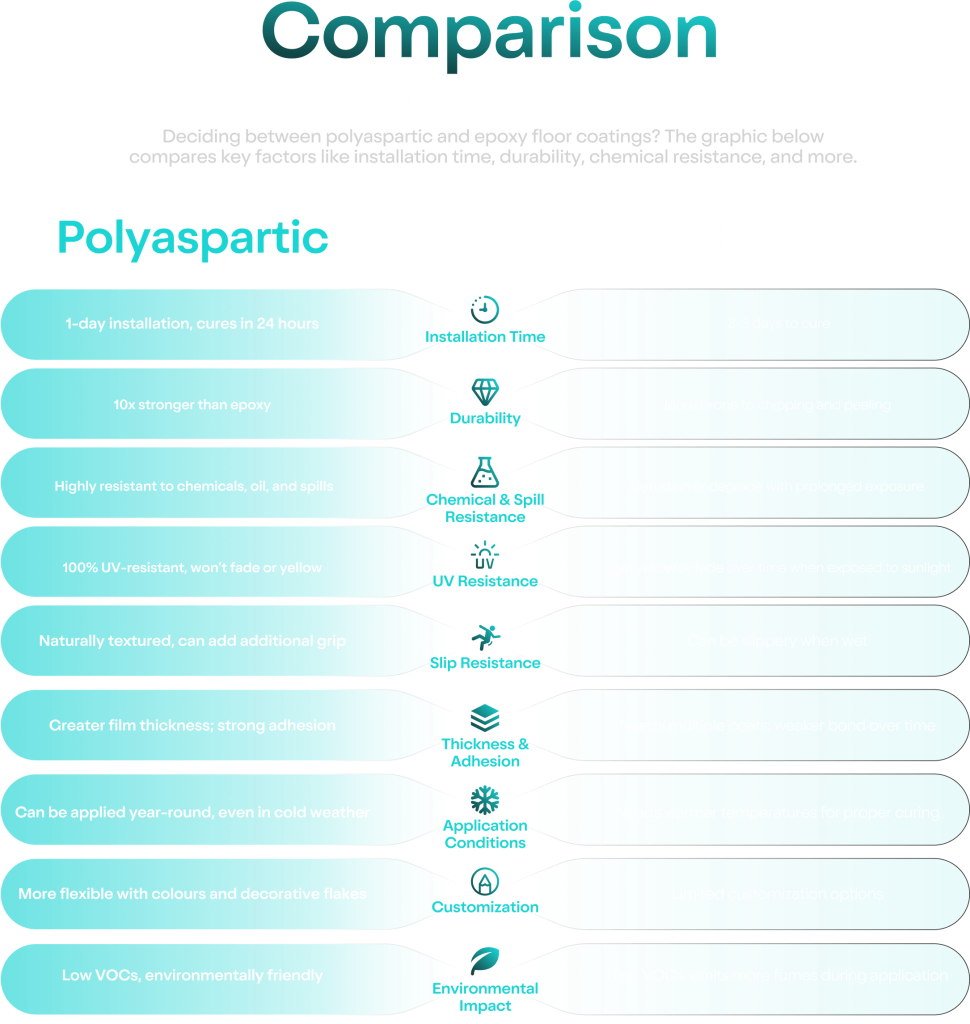

Garage floors take a beating. Between hot tires, road salts, oil drips, and dropped tools, your coating needs to be tough. Epoxy coatings are known for creating a hard, protective shell over concrete, but they can become brittle with time. Cracking, chipping, and UV discolouration are common issues, especially in climates with extreme temperatures.

Polyaspartic coatings are engineered to perform better in demanding conditions. They resist abrasions, stains, chemical spills, and UV exposure without breaking down. This makes them ideal for Canadian garages, where seasonal temperature swings are common. In fact, polyaspartic coatings have been shown to last significantly longer than epoxy, often 10 to 15 years with proper installation and care. Their flexibility allows them to expand and contract with the concrete, preventing cracks and delamination.

Did You Know?

A polyaspartic floor coating can withstand temperatures as low as -30°C and as high as 100°C, making it perfect for fluctuating garage environments in Canada.

Installation Time and Weather Flexibility

Time is a significant factor in homeowners’ choice of floor coating. Epoxy typically takes several days to install and cure, and it’s sensitive to temperature and humidity during the process. That can mean delays, especially in cooler months.

Polyaspartic coatings, however, cure quickly, usually within 24 hours. That includes both application and walk-on readiness. Many installers can even complete the job in a single day, allowing you to move back into your garage the next day. Unlike epoxy, polyaspartic systems can be applied in a wide range of temperatures, even in near-freezing conditions, so you’re not limited to a specific season.

This makes polyaspartic coatings an attractive choice for those who want minimal downtime and faster project completion.

Appearance and Customization Options

A quality garage floor doesn’t just need to be strong; it should look good, too. Both coatings offer a variety of finishes, but polyaspartic options are generally more customizable.

Epoxy provides a glossy finish and comes in multiple colours, but it tends to yellow or fade when exposed to UV light. That can be an issue if your garage gets a lot of natural light.

Polyaspartic coatings are UV stable, so they maintain their colour and gloss over time. You can also choose from a wide variety of colours, patterns, and textures — including decorative flake blends, clear top coats, and even metallic finishes. These design options let you match your garage’s aesthetic or create a showroom-style space that complements your home.

For homeowners who want both performance and visual appeal, polyaspartic delivers on both fronts.

Cost and Long-Term Value

Upfront, epoxy is the cheaper option. Material costs are lower, and some DIY kits are available for homeowners looking to do it themselves. However, the long-term value tells a different story.

Epoxy floors often need repairs, touch-ups, or full recoating within 3 to 5 years, especially in high-use environments. The cost of maintenance and potential downtime adds up over time.

Polyaspartic coatings have a higher upfront price, but they offer a better return on investment. Thanks to their superior durability, resistance to wear, and lower maintenance needs, they typically last much longer, sometimes twice as long as epoxy. For those planning to stay in their home long term, polyaspartic coatings can be a more cost-effective choice.

According to industry data, polyaspartic systems can reduce floor maintenance costs by up to 30% over their lifespans compared to traditional epoxy systems.

Conclusion: Which Garage Floor Coating is Better?

So, which option is better: polyaspartic or epoxy garage floor coating? While epoxy may appeal to budget-conscious homeowners, it often falls short in performance and longevity. Polyaspartic coatings, while slightly more expensive up front, offer faster installation, better durability, and long-term value. For Canadians who face seasonal temperature swings, daily garage use, and high moisture levels, polyaspartic coatings offer a stronger, more innovative solution.

At Quick Coat, we specialize in polyaspartic applications tailored for Canadian garages. If you’re looking for a floor that’s tough, beautiful, and built to last, we’re here to help.

Your Garage Deserves the Best — Trust Quick Coat

A high-performance garage floor starts with the right coating and the right team. At Quick Coat, we offer premium polyaspartic floor coatings designed to stand up to the toughest conditions. Our professional installers bring years of experience, top-tier materials, and an unmatched dedication to quality. Whether you’re protecting your investment or improving your home’s value, we’ll help you get there. Ready to transform your garage floor? Contact us today to get started.